Hydrostatic machine base for ultra-precision grinding center

04.02.2026

New standards in accuracy, dynamics, and surface quality;

Hyprostatik Schönfeld (Germany), the market leaders for hydrostatic components, has developed a high-precision hydrostatic machine base for a new ultra-precision grinding center for Optotech. The machine platform forms the heart of the system and enables a previously unattainable combination of dimensional accuracy, dynamics, and surface quality in the ultra-precision grinding of optical surfaces.

Rigid machine structure based on granite

The machine base is a solid granite bed, which creates ideal conditions for ultra-precision machining thanks to its thermal stability and stress free high precision. A cross slide with hydrostatic guide shoes moves on top, performing horizontal movements in the X and Y directions. The axes are driven by linear motors with high precision linear scales, enabling backlash-free, highly dynamic precise positioning.

Photo: The ultra-precision grinding center is equipped with a hydrostatic machine base from Hyprostatik Schönfeld.Ž

Source: OptoTech/Hyprostatik

Hydrostatic Z-axis with innovative drive concept

The vertical hydrostatic guided Z-axis in RAM design is mounted at the front of the granite bed. It is driven by a hydrostatic screw drive with hydrostatic bearing and torque motor. This allows higher dynamic and precision in more compact design than using linear motor. A weight balance is not necessary.

Maximum accuracy thanks to hydrostatic guidance technology

The extremely rigid construction of the machine and the finishing of all relevant components on hydrostatic grinding machines result in straightness of movement and positioning accuracy that is several times better than comparable systems with roller guides.

The slides float friction-free on hydrostatic pockets. This enables travel steps of less than 0.1 µm and a reversal play of less than 0.1 µm. Thanks to the contactless guidance, the axes operate completely wear-free and maintain their accuracy consistently over many years.

Photo: The device is designed for the flexible and universal production of spherical and aspherical optical components.

Source: OptoTech/Hyprostatik

Optimal damping for maximum surface quality

Another advantage of hydrostatic guidance is its excellent damping. This increases path accuracy, especially at high dynamics, and has a direct positive effect on the achievable surface quality of the workpieces. High accelerations also enable short machining times with maximum precision.

Hydrostatic workpiece spindle with excellent rotation quality

A hydrostatic workpiece spindle is mounted above the vertical axis. The axial and radial runout quality is less than 0.1 µm. This exceptional running quality is directly transferred to the dimensional accuracy and surface quality of the machined optical components.

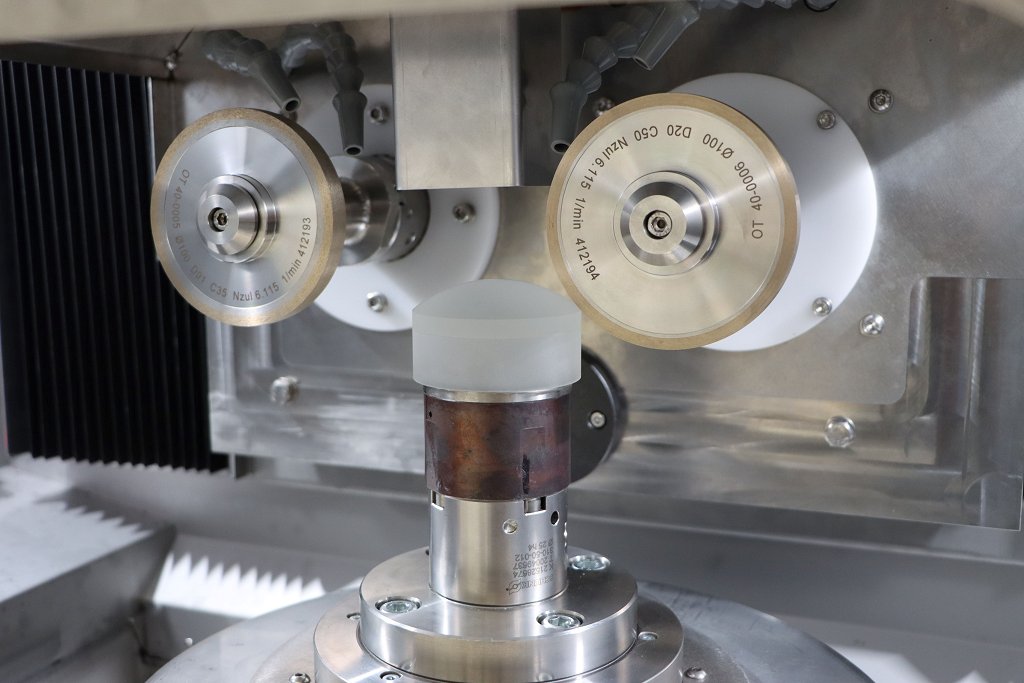

Photo: High-quality components ensure precise pre-grinding and fine grinding of spherical and aspherical lenses.

Source: OptoTech/Hyprostatik

Hydrostatic grinding spindle with excellent runout and damping

The hydrostatic grinding spindle with runout less than 0.1 µm and balance quality 10 times better than G0,4 grinds brittle and hard material with much reduced surface damage, which reduce polishing time drastically.

Source:

www.hyprostatik.de

www.schunk-group.com

www.optotech.net