Unlocking cost-efficient small series production with MJF

09.01.2026

Multi Jet Fusion is redefining small-series manufacturing by delivering production-ready parts without the cost or delay of tooling. At Speedpart, the technology has proven its ability to produce hundreds of functional components at just a few euros per unit.

Photo: MJF-produced PA12 part with functional honeycomb geometry — showcasing lightweight design potential, material efficiency and the capability for complex internal structures without tooling.

Source: Speedpart

Additive manufacturing is increasingly evolving from rapid prototyping into a possibility for functional series production. One technology playing a pivotal role in this transformation is Multi Jet Fusion (MJF). The process, introduced by HP, has now matured into a reliable industrial method, particularly attractive for economically viable small-batch production — without the costs and time for injection moulding tools.

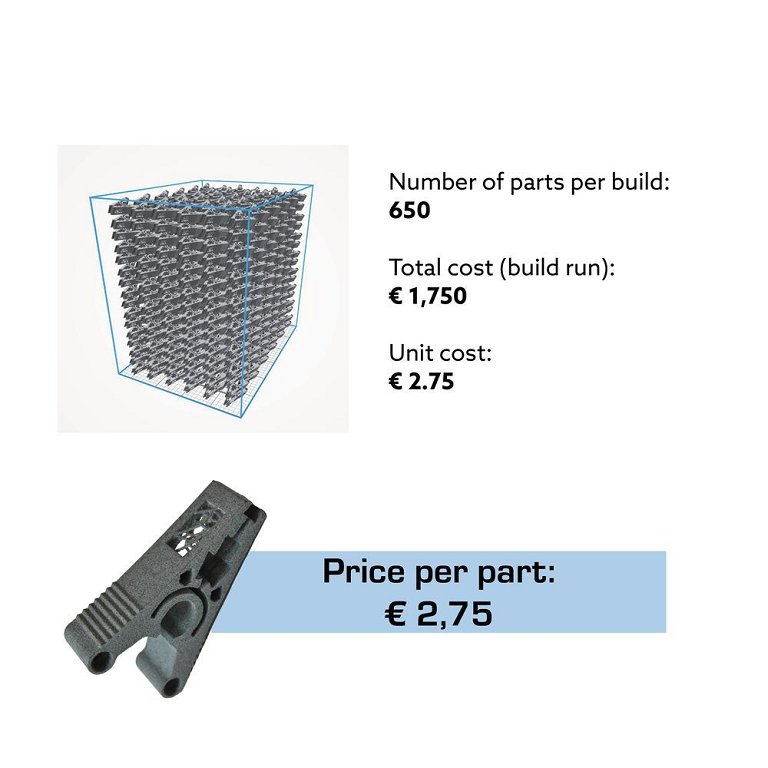

At Speedpart, the integration of MJF into the 3D printing portfolio has allowed a substantial expansion in the spectrum of applications. By showcasing a concrete example with more than 600 parts at a unit cost of just 2.75 euros, Speedpart recently demonstrated that additive manufacturing has arrived in the world of economic small series. The advantages of 3D printing are no longer limited to design freedom; today, it’s about speed, repeatability and cost-efficiency at scale.

Photo: Speedpart’s integrated technology portfolio: From additive to conventional methods.

Source: Speedpart

The capabilities of Multi Jet Fusion (MJF)

The MJF process is based on the selective application of fusing and detailing agents onto a polymer powder bed, followed by exposure to infrared energy. This results in homogeneous, isotropic components with consistent surface quality, dimensional stability, and mechanical strength. Unlike laser-based powder bed fusion, MJF enables faster print cycles, making it well-suited for serial production.

One of the key benefits lies in the consistent part performance across a build job. The parts exhibit high repeatability, making MJF an enabler of true serial production in industries where functional prototypes are no longer sufficient and cost-per-part plays a decisive role.

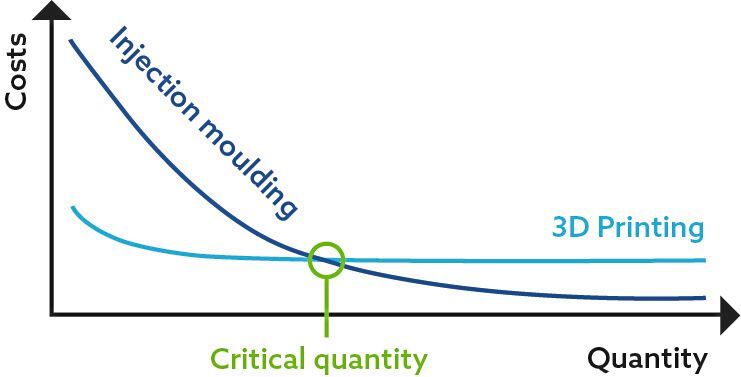

Photo: Cost-per-unit comparison (MJF vs. Injection Moulding)

Source: Speedpart

This positions the technology as a cost-efficient alternative to injection moulding for low-volume series, bridging the gap between prototyping and traditional serial production. In applications where tool lead times or high initial costs are limiting, MJF enables agile, tool-free manufacturing with short turnaround times and reduced part cost variability.

As a complementary process alongside vacuum casting and injection moulding, MJF delivers production-grade parts without the need for costly tooling — enabling a flexible, application-specific manufacturing strategy.

Economic viability: A real-world example

To demonstrate the commercial potential of MJF, Speedpart showcased a live build job at a recent industry trade fair. The featured part was a compact clip designed to cover laptop cameras, illustrating not only the economic viability but also the functional design freedom of MJF.

A single build job produced 650 functional PA12 parts at a total cost of 1,750 euros — translating to just 2.75 euros per part. With no need for moulds and no tooling investment, this example underscores the economic case for additive manufacturing in short-run production.

Photo: Cost analysis for a small-batch production using Multi Jet Fusion. Disclaimer: The figures presented are based on an actual production job and are intended for illustrative purposes only. Customised part calculations using the MJF process are available upon request.

Source: Speedpart

This benchmark illustrates how 3D printing can offer a competitive alternative to conventional technologies such as aluminium or steel tooling for injection moulding, especially in volumes ranging from 100 to 2,000 units. For development projects, pilot runs, market tests or pre-series production, MJF delivers scalable and financially viable output.

The precise break-even quantity, however, strongly depends on the specific part geometry, size and functional requirements — and must be calculated individually for each application.

One of MJF’s defining strengths is its ability to produce complex geometries — including undercuts, integrated clips, living hinges, and lattice structures, without compromising part integrity or requiring assembly. These features are often difficult or impossible to achieve with conventional manufacturing techniques.

Photo: Compact camera clip for laptops, manufactured additively in PA12 in a 650-unit batch as an example of cost-efficient small series production.

Source: Speedpart

Depending on the intended application, parts can undergo black dyeing, chemical vapour smoothing, polishing, blasting or surface structuring. These finishing options not only fulfil visual and tactile requirements for customer-facing elements but also provide functional enhancements, such as hygienically optimised finishes for medical use.

Time-to-market advantage in agile product development

Speed and responsiveness have become critical drivers in modern product development cycles. Traditional small series manufacturing typically involves extended lead times due to mould design, iteration and tool production. Digital small series shorten this cycle dramatically. Digital workflows enable parts to move from CAD to final product in just a few days, allowing companies to respond more flexibly to market demands, reduce inventory risk and iterate faster.

For OEMs and engineering teams, this results in:

- Faster iteration loops

- Early field-testing of functional parts

- Minimised inventory and warehousing costs

Technology boundaries and complementary alternatives

While Multi Jet Fusion offers a compelling solution for many low-volume production scenarios, it is not universally applicable to all parts or technical requirements. As with any manufacturing process, certain limitations must be considered — particularly when it comes to material-specific properties, part dimensions, and functional tolerances.

Photo: Surface comparison of MJF parts made from PA12: left — untreated natural finish; centre — chemically smoothed; right — chemically smoothed and black dyed. Post-processing enhances both aesthetics and surface functionality.

Source: Speedpart

For example, where series-identical materials are mandatory, alternative processes such as vacuum casting or injection moulding may be more suitable. At Speedpart, these technologies are fully integrated into the production portfolio. This enables the company to evaluate and compare different manufacturing routes in terms of cost, quality and feasibility. For each application, the experts calculate the critical quantity based on part geometry, material and requirements.

This allows the manufacturer to provide its customers with a recommendation in the early consultation or quotation phase — ensuring the most cost-effective and technically appropriate solution is selected, whether it involves additive, hybrid or conventional methods. This way, customers can make data-driven, economically sound production decisions, regardless of part volume, geometry or complexity.

A strategic manufacturing tool for small series

3D printing is no longer confined to prototyping applications. It has matured into a scalable, efficient and industrially reliable production process, especially where cost control and agility are paramount.

Photo: Functional plastic components with Multi Jet Fusion: ideal for prototypes, small series and industrial applications.

Source: Speedpart

Multi Jet Fusion provides a valuable tool for closing the gap between prototypes and mass production. By removing the dependency on tooling, reducing unit costs, and enabling supply chain flexibility, it strengthens competitiveness in fast-evolving markets.

As demonstrated by Speedpart’s recent live case, additive manufacturing can already compete with conventional methods in terms of both economics and performance — and that makes MJF a key component of modern production strategies.

At Speedpart, this mindset drives every project — from rapid prototyping to production-ready parts across all major technologies. (ast)

Published on: www.etmm-online.com

More information: www.speedpart.de