Market innovations from Peiseler at the EMO

02.09.2021

The industry's first in-person trade fair since the pandemic creates the ideal setting for new developments with high customer benefits

EMO Milano is the long-awaited highlight of the year for the machine tool and metalworking industry since the start of the Corona pandemic. This makes it exactly the right occasion for Peiseler to present new solutions promising a high level of customer benefit in a form not yet seen on the market. In the middle of this trade fair appearance of the leading manufacturer of trunnion tables, index tables, two-axis rotary tilt tables, swivel heads and workpiece changing tables are two highlights that will likely attract the attention of trade visitors. Peiseler, headquartered in Remscheid, will be showing both a completely newly developed fork-type milling head and a new two-axis rotary tilt table. Both of these are absolute innovations on the market in view of some of their properties.

With the SSK 400, Peiseler has also expanded its product portfolio in the area of fork-type milling heads. "In numerous discussions with our customers, we first identified the features that are of particular importance to users and that have not yet been adequately satisfied by the market," says Marc Gronau, Sales Manager at Peiseler, describing the history of the development of the new device. Using this as a basis, the designers paid special attention to optimizing important features. In doing so, they relied on tried and tested components that have long been used in the company's other dividers.

For the new SSK 400 fork-type milling head, Peiseler has completely redeveloped the drive with an innovative motor cooling concept. Photo: Peiseler

The result is impressive: in particular, they have succeeded in developing a completely new motor cooling concept that has not yet been seen on the market. This enables dissipation of the heat generated by the torque direct drives, allowing a previously unattained power density. This allows significantly increased accuracy compared to the competition, along with a considerably higher continuous torque in the identical installation space. In addition, Peiseler has optimized the FEM weight of the housing structure while simultaneously creating a thermally stable design. Generously dimensioned axial radial bearings also ensure maximum precision and rigidity.

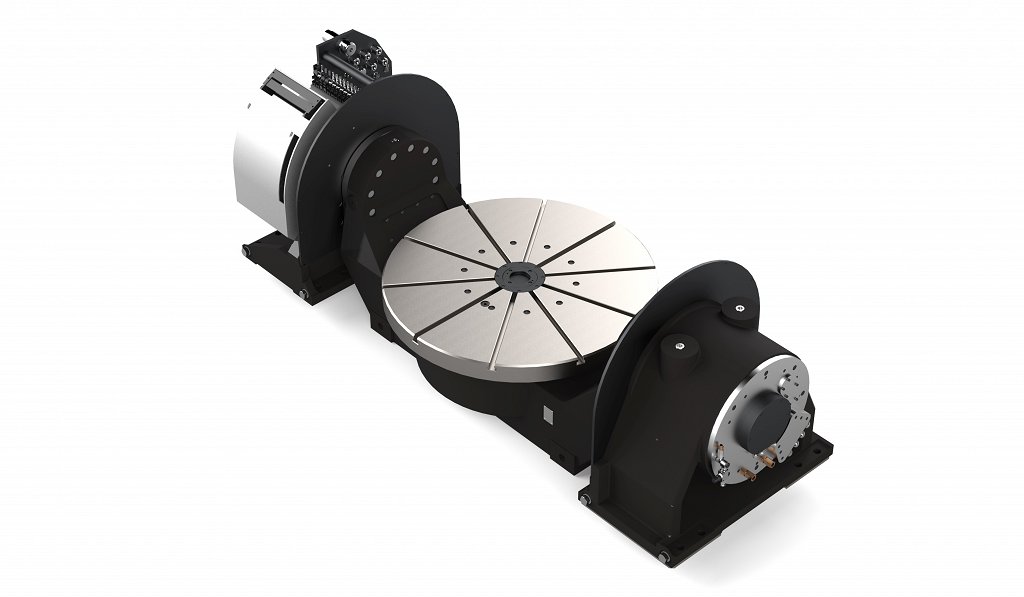

Two-axis rotary tilt table with unique drive train

Peiseler is also presenting a market innovation to the trade public in Milan with the new ZASG 400 two-axis rotary tilt table. The design engineers in Remscheid have also completely redeveloped the drive for this. "The combination of a torque motor with a torsionally stiff and backlash-free coaxial gear is a real market innovation," emphasizes Gronau. With functionality comparable to other swiveling devices from Peiseler, it was possible to significantly reduce the required torque level in the electric drive upstream of the gearbox. This downsizing has reduced the energy requirement for drive power and cooling by up to 75 percent. The elimination of a second motor, made possible by the gearbox, also contributes to this, offering more space in the control cabinet and reducing its footprint. This also saved about a quarter of the weight.

The ZASG 400 two-axis rotary tilt table presented at the EMO uses a torque motor connected to a coaxial gearbox for the first time on the market. Photo: Peiseler

The new technology of the ZASG 400 and the reduction in parts realized in the process lead to a significant reduction in the total cost of ownership. "Here we are confident that with this new two-axis rotary tilt table and its excellent price-performance ratio, we are presenting a solution at the right time that will help to strengthen our customers' market position." EMO Milano, as the first in-person event for a long time, is the ideal setting for this, just as it is for the presentation of the new SSK 400 fork-type milling head.