Leading Slovenian manufacturer benefits from use of WITTMANN Group equipment

26.02.2021

For over 45 years, TEM Čatež d.o.o., located in the eastern part of Slovenia, has been producing and offering its clients easily adaptable, technologically innovative and aesthetically pleasing electric switches and sockets for a variety of living and working spaces. With the delivery of the first SmartPower 110 multi-component injection molding machine in 2017, a fruitful cooperation between TEM and ROBOS (the Slovenian/Croatian WITTMANN Group agent) came into life. The cooperation has continued to this day, with many completed projects – and lots of upcoming projects for the future.- Peter Zajc

TEM Čatež d.o.o. truly is the regional leader in the production of a comprehensive selection of switches and sockets for both simple and more demanding installations.

Over the years, TEM has successfully promoted its brand and achieved wide recognition for its products. The company concentrates the entire technological and production processes in one place – that is the own production plant located in Velika Loka.

It is important that every product is recognized by TEM’s customers and that new products are constantly developed. The main customers for the business are specialized distributors of electrical equipment and electrical installation materials. TEM’s switches and sockets are sold in a total of 25 European countries. In recent years, the company had grown by more than ten percent per year on average.

The company was founded in 1973. Over the decades, various modern technological and manufacturing processes have been introduced, including: stamping, turning, Bakelite injection, multi-component injection, assembly and other processes. Thus, TEM was always equipped to control all manufacturing in-house.

TEM as WITTMANN BATTENFELD customer

In the year 2017 – due to the growing demand for their products –, TEM ordered the first injection molding machine from WITTMANN BATTENFELD: a specially colored SmartPower MC 110/350H-60S B8 with rotary table and a PRIMUS 16 WITTMANN robot that was fully integrated in the B8 machine control. This machine replaced the previously system of overmolding parts using two other machines.

This change led to significant energy-savings, as well as a reduction of the total cycle time and to the redeployment of labor.

After the first project was successfully completed, a discussion began with regard to a centralized material handling system. This project was finally realized in 2018, with the opening of a new production facility. Equipment from WITTMANN was chosen, because the technology offered the best price/performance ratio in line with the needed solution. The material handling system was installed using different models of WITTMANN material dryers: 2 ATON basic G70-100-M, 2 ATON basic G70-200-M, 1 ATON basic G120-300-M with controlled vacuum take-off adapter. The existing DRYMAX E60 drying equipment was also integrated into the new system.

TEM also acquired and deployed FEEDMAX G206-50 and FEEDMAX G203-50 loaders, all equipped with swiveling IMM hopper adapters. The system also featured an XMB Filter Station, a CODEMAX Coupling Station, and was equipped with a WITTMANN TEACHBOX basic control.

Shortly thereafter, TEM ordered another injection molding machine: a SmartPower 90-210 B8 with special options such as HiQ Flow®, measuring the resistance of the melt flow during a specific phase of the injection process. This special functionality compares the actual value with a previously set value, and adjusts the holding pressure parameters (change-over point) within the respective cycle. The benefit for the customer is a greatly increased quality of injection molded parts, and therefore much less production waste. This machine was also automated using a WITTMANN PRIMUS 16 robot.

In addition, some of TEM’s existing injection molding machines were equipped with new WITTMANN robots (mostly PRIMUS 16 and PRIMUS 14), and also with new TEMPRO primus C90 mold temperature controllers. Within the scope of a test phase, there is also a variothermal temperature controller in use. This is being used to check whether the technology may be effective in the production of parts with optically challenging surfaces, perhaps even improving the impression of the parts in this regard.

The basis of a good and successful industrial partnership always lies in providing great sales support and technical support in all aspects of plastics processing technologies – especially with regard to a newly-won customer. WITTMANN Group and ROBOS are very mindful of the dynamic involved and quickly rose to this challenge, providing quick and effective response to all customer concerns and laying the groundwork for further successful cooperation.

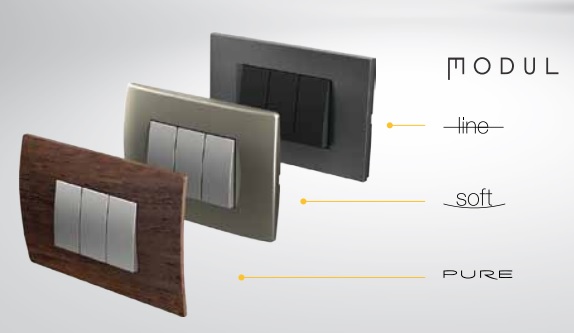

MODUL modular system of switches and sockets in Line, Soft and Pure design lines.

MODUL modular system of switches and sockets in Line, Soft and Pure design lines.

Peter Zajc is Managing Director of ROBOS d.o.o. in Ljubljana-Črnuče, Slovenia, the WITTMANN Group Agent for Slovenia and Croatia.