Comparing 3D-Printed Conformal-Cooled Steel Molds to Aluminum Molds

16.09.2020

While 3D-printed conformal coolant lines in steel injection molds reduce production costs and improve part quality, aluminum molds can yield similar results faster and at a lower cost.

3D printing has made great strides in both technological advancements and manufacturing production implementation. One proven application that many companies have implemented is using 3D printing to build cooling channels close to the contours of a mold’s internal cavity walls, helping to reduce cycle times.

3D-printed conformal cooling channels also funnel the liquid coolant at a constant distance from the injected plastic melt pool. This produces a better part without the warpage, sink marks or other defects characteristic of standard steel mold production.

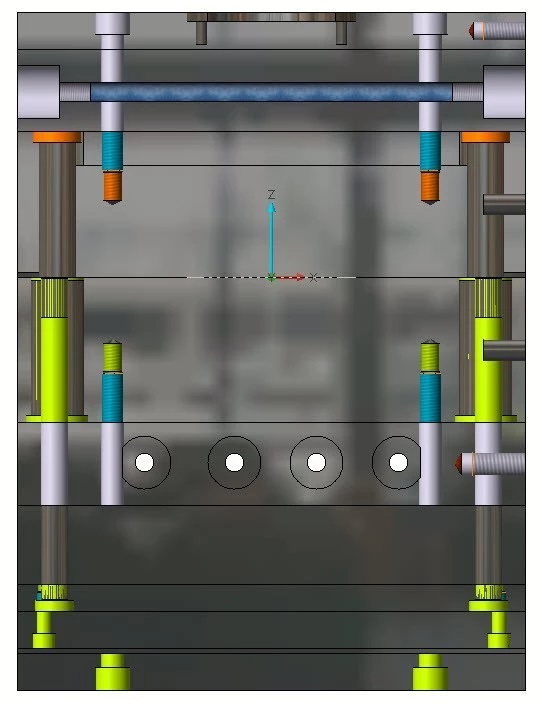

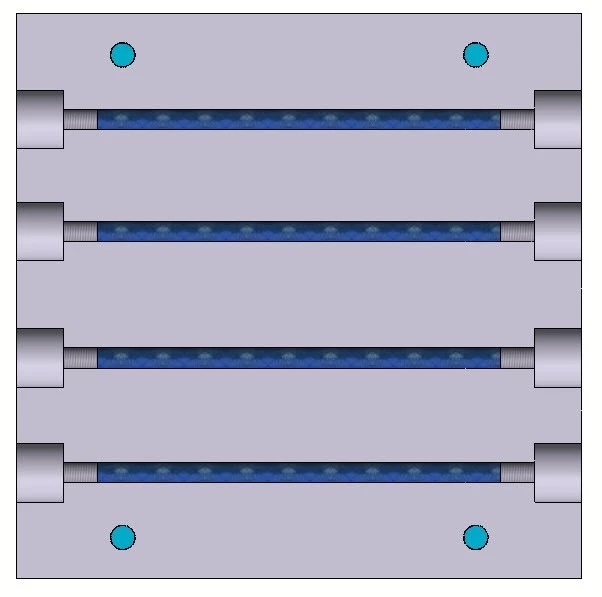

This 12 by 12 aluminum mold base has coolant lines through the upper and lower support plates. Image courtesy of American Quality Molds.

Transparent rendering of a solid model of the 12 by 12 aluminum mold base showing typical straight-through coolant lines in the upper and lower support plates. Solid models provided by TST Tooling Software Technology LLC.

This solid model section view demonstrates the simplicity of adding coolant lines in an upper support plate (similar to that machined into the lower support plate), which is the most common method of adding coolant lines in aluminum molds, although other configurations are sometimes used such as intersecting coolant lines with internal plugs to direct the flow (not shown).

The bottom line is the use of proper conformal cooling channels in a steel plastic injection mold will produce better parts faster, permitting the molder to be more competitive and make more money, if the production run is long enough to recover the upfront costs.

However, there are upfront costs when generating conformal cooling channels using 3D printing — for example, access to a 3D printer and trained operators. Computational fluid dynamic (CFD) simulation software is another essential tool. If a designer does not properly model flow through the cooling channels, differential cooling will produce products that are worse than if a standard steel mold produced them. Cycle times may suffer even if the product quality does not suffer.

On top of the software is the CFD analysis. Depending upon the complexity of the part, it is not unusual for a CFD simulation to take weeks to complete, which must be completed before one can start cutting metal. The CFD analysis must properly represent the unique characteristics of the conformal cooling channels within the CFD software to conduct a proper analysis.

Once the mold is in production, there are other concerns and costs. The cooling channels are now mere millimeters below the molding cavity surface, so cleaning and handling the mold takes extra care.

Another production concern is a more rapid buildup of sediment within the internal cooling passageways caused by the extra twisting of the cooling channels to achieve a greater level of desired turbulent flow (in opposition to laminar flow in standard molds with straight-through channels). A toolroom can mitigate the buildup to a great degree by flushing the inserts with an acid solution and using a closed-loop filtration system.

The Aluminum Option

It would not be prudent to replace all steel molds with aluminum molds, as many applications demand a steel mold, and in these cases, companies should consider 3D-printed conformal cooling. However, aluminum molds are far more capable of achieving long-term production than is often thought. Tests have demonstrated that aluminum molds can achieve similar production rates and part quality improvements equivalent to those gained by 3D-printed conformal cooling channels in steel molds.

Aluminum grades used for plastic injection molds include large cast plate-like M1, medium-grade aluminum such as 6061, and very high strength grades like 7075-T651 and Arconic’s QC-10™, among others. This is no different than having a large variety of steels available for making plastic injection molds. There are at least 19 different steels typically used for plastic injection molds, with some others employed for specialized applications. Plus, material innovators continue to develop aluminum and steel alloys for all mold types molds.

The most common knock against using aluminum for plastic injection molds is its softness. Compared to hardened steels, that is true, but concerning many plastic injection mold applications, aluminum produces better parts than a steel mold. Because aluminum is a soft material, it tends to even out the microscopic molecular hills and valleys while in use over time. Instead of galling, aluminum surfaces slide. If properly used, studies have documented aluminum molds producing more than 2 million shots.

While aluminum molds have shown excellent wear resistance for a wide variety of resins (including glass-filled), there is concern about the new fiber-infused resins that provide greater part toughness and durability. These resins can generate significant wear on steel molds, so the use of hard coatings is vital to reduce wear, and even restore, steel molds running abrasive resins.

Aluminum molds can be successfully hard coat anodized to provide an Rc65 surface, but the finish is about 0.002-inch above the finished aluminum substrate (plus another 0.002-inch embedded in the substrate). Also, hard coat anodizing can “chip away” from corners that are 90 degrees or less. Once this occurs, you must strip the anodized surface and re-anodize to repair the mold. Research and testing on various surface treatments to address the wear issues involving the use of aluminum molds for the new abrasive resins are underway.

Before deciding to use an aluminum mold, answer the following five questions as you would if considering the use of a low-cost “soft” steel:

Is the resin conducive for aluminum?

What is the geometry of the part to be molded?

What is the quantity?

What is the desired cycle time?

How long does the mold need to last?

Despite all the coverage of 3D-printed conformal cooling channels in a steel mold, a standard aluminum mold remains a viable option. Properly using aluminum for plastic injection molds can yield many of the same advantages as conformally cooled molds. For example, longer material flow distances with less injection pressure, which permits molds to fill faster and more efficiently.

Source: www.moldmakingtechnology.com