Digital and automated production

10.06.2019

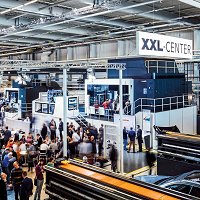

New paths towards digital and automated production as well as additive manufacturing with powder bed technology will be showcased by DMG Mori at Moulding Expo.

DMG Mori will be presenting a cross section of its extensive machine portfolio at Moulding Expo. The exhibition program comprises the CMX 600 V vertical machining center, 5-axis machines such as the DMU 50 3rd Generation and DMU 60 eVo as well as models from advanced technologies. These include the Ultrasonic 20 for ultrasonic processing, the recently presented Lasertec 125 Shape for surface structuring and the Lasertec 30 SLM 2nd Generation from the field of additive manufacturing.

DMG Mori will be presenting a cross section of its extensive machine portfolio at Moulding Expo. The exhibition program comprises the CMX 600 V vertical machining center, 5-axis machines such as the DMU 50 3rd Generation and DMU 60 eVo as well as models from advanced technologies. These include the Ultrasonic 20 for ultrasonic processing, the recently presented Lasertec 125 Shape for surface structuring and the Lasertec 30 SLM 2nd Generation from the field of additive manufacturing.

Added value at all levels of production

DMG Mori sees digitalisation with strategic future potential. The technology leader will present pathways towards networked production at Moulding Expo under the catchphrase integrated digitisation. For DMG Mori this includes the control and operating system Celos, which enables digital monitoring of production based on numerous APPs. The Messenger, for example, visualises the current status of the machines on the shopfloor. The Condition Analyser uses sensor data to show the condition of machine components.

The Performance Monitor makes it possible to capture, analyse and visualise overall system efficiency taking into account machine availability and component quality. In addition Istos Planning Solutions assists users in the digital planning of processes such as material management, personnel resource planning as well as detailed production planning and order tracking.

Digital service solutions such as Netservice and WERKBLiQ round off the topic. Netservice makes it possible for machine operators, service experts and service technicians to interact in a remote-service session by means of a multi-user conference and the Servicecamera and thus quickly find a joint solution for service issues. WERKBLiQ ensures secure and complete documentation of maintenance processes and offers simple and cross-departmental communication.

Automated machines are crucial components of a digital factory and are therefore an integral part of Industry 4.0. The joint venture DMG Mori Heitec supports DMG Mori in the development and realisation of flexible automation solutions, such as workpiece handling. The automation expertise for pallet handling is directly integrated in the production plants of DMG Mori.

The interplay between engineering from the DMG Mori production plants and automation expertise on the part of DMG Mori Heitec provides the user with a customised, integrated and reliable solution – and everything from a single source. Additional service features from DMG Mori Heitec comprise configuration through to the operation of the system – including the modification or expansion of a system for additional products. DMG Mori will be presenting a DMU 75 monoblock and a CMX 600 V at Moulding Expo, each equipped with a PH 150 pallet handling system that has a maximum loading capacity of 250 kg and space for twelve pallets.

Two powder bed processing chains

As a global full-liner with over 20 years of experience in additive manufacturing of metallic components, DMG Mori stands for innovative manufacturing technology and worldwide service. DMG Mori offers the Lasertec SLM series (Selective Laser Melting) for additive manufacturing with the powder bed method. The Lasertec 30 SLM 2nd Generation has a 300 × 300 × 300 mm build volume and offers optimum user comfort. Material changes in less than two hours are possible thanks to the rePlug powder module, which of course guarantees a high level of both process autonomy and industrial safety. Two process chains can be realised with powder bed technology: On the one hand, workpieces produced by means of additive manufacturing can be finished to the required surface quality on a milling machine such as the 5-axis DMU 50 3rd Generation. On the other, the Lasertec SLM machines can finish previously milled base plates and bases without any need for support structures.