Replique expands global manufacturing partnership with Alstom

21.01.2026

By expanding its global manufacturing partnership with Alstom, Replique is strengthening flexible, decentralised parts supply for rail applications worldwide. From series production to legacy spare parts, the collaboration demonstrates how digitally enabled manufacturing can support efficient and reliable rail operations across multiple regions.

Replique, a production platform for industrial components, is expanding its collaboration with Alstom worldwide. What began with initial projects, such as door stoppers and tank caps, has grown into a long-term partnership. The company now serves as a global supplier for numerous projects and subsidiaries, including locations in Singapore, Brazil, Australia, France, Italy, Germany, Thailand, and Spain.

Photo: Branding plate for Alstom trains produced in series

Source: Replique

Replique has already produced volumes in the lower five-digit range for Alstom. These parts — made from materials ranging from stainless steel to flame-retardant plastics — are in daily use across railway operations, with all of them meeting Alstom’s specific testing and qualification requirements.

“We are proud to provide Alstom with global solutions that make their parts supply more efficient and flexible. Our components are used in series production, and each project highlights the diverse challenges of parts procurement while motivating us in our vision of a globally connected, sustainable, and efficient supply chain,” says Dr. Max Siebert, CEO and Co-Founder of Replique.

Photo: 3D printed impeller of metro cooling unit

Source: Replique

The breadth of the partnership is reflected in its application range. In Asia, an impeller used in a metro cooling unit required replacement. As the original manufacturer proposed exchanging the complete assembly, Replique produced the individual component and managed the full process, including metal additive manufacturing, balancing, precision machining and application of a corrosion-resistant coating. This approach enabled a faster return of the locomotive to service.

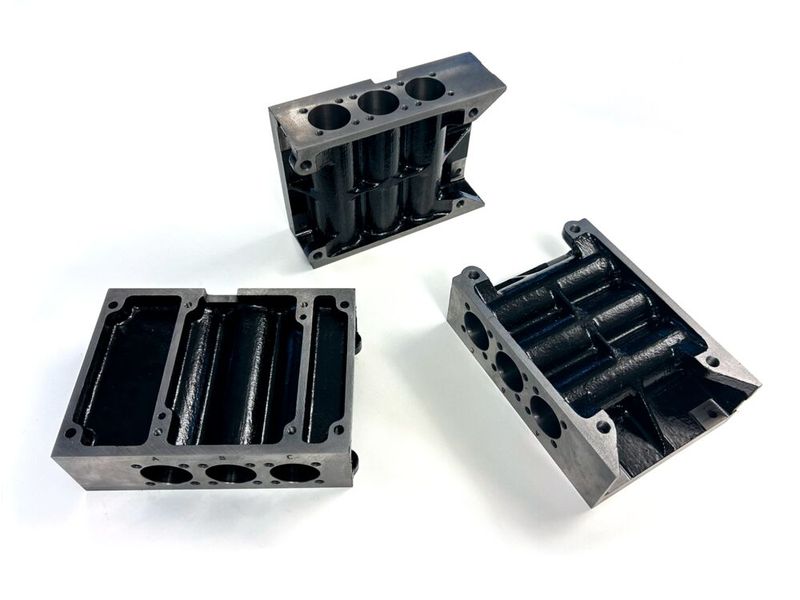

In Italy, Replique supplied cast intercoolers to return a 1960s-era train to operation. With the former supplier no longer available, production was secured using additively manufactured casting molds, ensuring continued spare-part availability.

Photo: Intercoolers produced using 3D-printed casting moulds

Source: Replique

For new train series from Alstom, Replique also provides branding plates for global deployment. “Replique doesn’t just deliver the components; it ensures consistently high quality across the globe, which is especially crucial for series production,” explains Lorenzo Gasparoni, Alstom 3D Printing Program Manager. “Replique also completed the entire series approval process, including First Article Inspection and First Article Mount – with excellent results.”

Published on: www.etmm-online.com

Source: Replique