Empower Your Aluminium Machining

16.09.2024

For many years now, aluminium materials have been becoming more and more prevalent in many industries. This trend continues unabated. While light-weight construction and corresponding materials and structures have always been an important aspect of aerospace, the use of aluminium to reduce weight in automobile manufacturing has increased steadily, and has really taken off now due to electromobility. MAPAL is a leading technology partner for machining aluminium components thanks to its many years of experience designing, producing and applying tools for aluminium machining.

Material knowledge vital to optimal machining processes

Aluminium and aluminium alloys are in principle easy to machine. As the cutting forces are low, high cutting data and in particular long tool life can be achieved with appropriate process planning. However, aluminium alloys have some special features which must be mastered. The geometry of the component and ever-increasing demands on tolerances and process capability pose additional challenges when machining aluminium.

Aluminium alloys can basically be subdivided into the principal categories of cast alloys, wrought alloys and powder-metallurgical alloys, whereby mainly the first two play a role in machining. For cast alloys, various alloy elements and corresponding casting methods are utilised to create the desired properties of a component. When casting, it is important to come as close as possible to the component’s final form to simplify mechanical machining. This “near net shape” technology has become established in mass production in particular.

When machining casted parts, the silicon content is decisive with regard to the alloy element as it has a powerful effect on wear and tool life. For wrought alloys as well, the desired properties can be brought about by the alloy elements. The silicon content is lower here, though, enabling chipless ductility. Other alloy elements are used here though to achieve good strength and stability as well as fatigue strength. Cold- or warm-worked alloys are the result, which can be processed into wrought material and then be machined.

Solutions for part production and assembly in aerospace

The aerospace industry deploys MAPAL tools both for part machining – i.e. manufacturing components that are assembled to form sections of the fuselage or wing – as well as for the final assembly where the individual sections of the entire aeroplane are put together.

When part machining aluminium parts, the part is frequently machined from solid material. Machining rates of over 90% call for an efficient volume machining to machine as much raw material in as little time as possible. Powerful tools are key here. The tools must meet a widely variety of requirements in final assembly. Not only is aluminium frequently utilized here, other light-weight materials like titanium and fibre-reinforced plastics are also used in one machining step. These so-called stacks are material combinations that pose a particular challenge as the machining characteristics of the combined materials are very different and the tools have to meet their varying requirements.

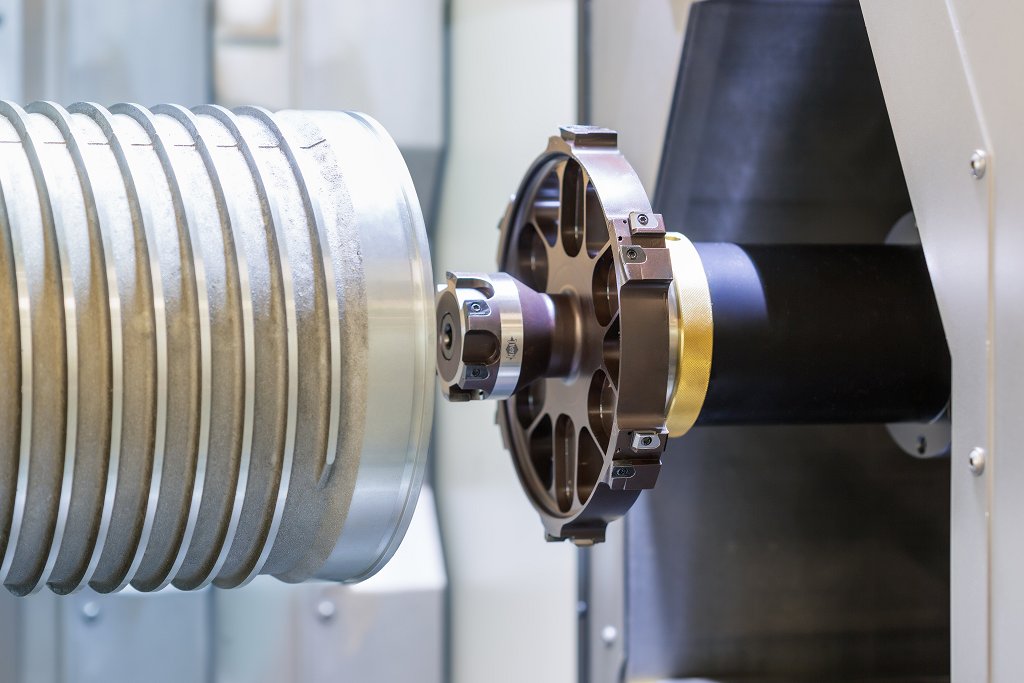

Machining rates of over 90% are standard in parts production in the aerospace industry. The NeoMill-Alu-QBig indexable insert milling cutter from MAPAL performs outstandingly for volume machining of aluminium. ©MAPAL

Machining rates of over 90% are standard in parts production in the aerospace industry. The NeoMill-Alu-QBig indexable insert milling cutter from MAPAL performs outstandingly for volume machining of aluminium. ©MAPAL

The aerospace industry has been using aluminium for many years to save weight. Besides the favourable relationship between stability and weight, this material also meets other requirements such as corrosion resistance, fatigue strength and low embrittlement. Therefore, there is high demand for machining solutions for aluminium in part production as well as in final assembly for aeroplanes.

More range with every kilogramme saved

Weight reductions are a primary concern in the development of electric vehicles as well. After all, every kilogramme saved means more range and less CO2. In mechanical machining for electric vehicles, established processes and tools are very good for producing some of the parts. However, there are inevitably new systems and components in e-vehicles that have to be redeveloped due to their function in terms of geometry and precision and/or material properties. Precision tool makers are called upon to deliver answers when it comes to scaling production volumes in the automotive industry and the habitual demands on process stability, consistent parts quality and attractive price levels.

One example of special requirements are the electric motor housings. The large stator bore with a diameter tolerance in the IT6 to IT7 range as well as circularity and cylindricity of 20 to 30 µm or less, combined with other functional surfaces for accommodating rotors and transmission elements, requires the highest degree of precision with regards to shape and precision tolerances.

Stator housings of an electric motor place particular demands on precision for machining. The weight-optimised fine boring tool with HPR400 technology for machining the stator housing fulfils all requirements for process reliability. ©MAPAL

Stator housings of an electric motor place particular demands on precision for machining. The weight-optimised fine boring tool with HPR400 technology for machining the stator housing fulfils all requirements for process reliability. ©MAPAL

The large battery trays are another example. Their main structure consists of extruded profiles made of aluminium with low silicon content. The challenges here are to keep chip and burr formation under control and to machine the very large parts using economical cutting data without vibration. This also applies to the trend towards mega and giga casting where large-scale structural parts are no longer made of individual parts but are cast as a single piece. The components’ large size and tendency to vibrate call for special tool geometries for low-vibration machining with a high degree of precision. New long-chipping aluminium alloys whose machining characteristics must first be mastered represent a further, related challenge.

Aluminium is also used in many other industries thanks to its properties. Depending on production volume and number of variants, manufacturers use standardised machining solutions for parts where a significant amount of machining is required. Here too there are aluminium parts produced in high quantities, which require very sophisticated customised concepts. In fluid power, for example, parts like pneumatic valve housings and pneumatic cylinders are produced in large quantities. For industries with high variance and small quantity, standardised tool solutions make sense.

Wide-ranging product and application portfolio for aluminium

MAPAL has developed an extensive product and application portfolio thanks to many years of experience and countless proven solutions in the field of aluminium machining. The range includes established bore machining applications like fine boring, reaming and boring. MAPAL’s guide pad technology for fine boring achieves the highest degree of precision for diameter, circularity and cylindricity. For tools with fixed blades for reaming and boring, MAPAL offers a one-of-a-kind range for PCD tools. It includes everything from tools for a single diameter with chamfer to very complex tools for multi-stage bore geometries. For drilling into solid, there is also a large selection of solid carbide drills and drills with indexable inserts. Deep drilling and dry drilling are a particular challenge as special geometries and expertise are required for both.

For the milling of aluminium, MAPAL offers a broad range that includes face milling cutters, high-volume milling cutters, end milling cutters and special designs. Series with cassettes, inserts or a fixed design are available for face milling cutters, for example. PCD and different varieties of carbide are used as cutting material and can be supplied for various cutting depths in combination with the required surface finishes and profiles. In this way special cross-cut structures can be created for sealing faces, for example. In addition to the universally applicable range of end milling cutters made of solid carbide or with PCD blades, MAPAL has products that cater to special requirements such as high precision, parts vulnerable to vibration or high-volume machining.

MAPAL uses application-specific chip-breaking geometries for defined chip breaking of aluminium materials with low silicon content. In this way, MAPAL achieves good chip breaking and defined chip lengths and thus the highest performance and process reliability. ©MAPAL

MAPAL uses application-specific chip-breaking geometries for defined chip breaking of aluminium materials with low silicon content. In this way, MAPAL achieves good chip breaking and defined chip lengths and thus the highest performance and process reliability. ©MAPAL

Engineering for perfect aluminium machining

The product range and extensive manufacturing expertise form the basis for optimal machining processes for aluminium parts. But the tool itself is not the only factor. Only through the art of engineering can the wide-ranging product and application portfolio provide the perfect solution. And this is where MAPAL’s true strength lies. Considerable experience developing new solutions time and again for the production of aluminium parts make the tool manufacture a first-class solution provider in this area. And the customer takes centre stage here.

According to the MAPAL philosophy, the perfect solution can only be the one that is precisely tailored to the needs and requirements of the customer. The expectation is not over-engineering but rather machining processes designed based on requirements. MAPAL sees itself as a solution provider and technology partner and, as opposed to a conventional tool supplier, does not only consider technical aspects but also tries to put itself in the customers shoes. This customer-centred focus is behind the “Basic - Performance - Expert” solution approach and enables MAPAL to tailor the tools to the customer’s requirements.

For more information, please visit: www.mapal.com