Great success for ENGEL with technological innovations and customer focus

12.06.2024

After an impressive week at NPE2024 in Orlando, Florida, ENGEL can draw an extremely positive balance. Between May 6 and 10, the company showcased its latest innovations and technologies. ENGEL remains true to its reputation as an innovation leader – not only through the continuous development of its product range, but also through its customer-focus and technical support. This emphasised ENGEL's commitment to provide advanced technologies to its customers.

ENGEL Exhibition Stand NPE 2024

ENGEL Exhibition Stand NPE 2024

The most important facts

After a 6-year break, the trade fair attracted over 55,000 visitors. Many of them were particularly interested in ENGEL's innovative machines and technologies. These products were developed not only to demonstrate technical progress, but also to respond specifically to customer requirements and challenges. The injection moulding machines on show therefore proved to be a crowd magnet:

The new e-mac slim edition offers maximum mould installation space with a reduced and very compact footprint.

The hybrid e-speed 610/90 enables particularly high injection pressures and speeds for the production of thin-walled packaging with the highest performance requirements.

ENGEL e-speed 610 for high-performance applications/ Exhibit NPE 2024

ENGEL e-speed 610 for high-performance applications/ Exhibit NPE 2024

The hydraulic, tie-bar-less victory 330/85 enables quick and easy mould changes, which minimises downtimes and increases productivity.

The e-motion 440H/160TWP combi M optimises the production of two-component products in the tightest of spaces under cleanroom conditions using cube mould technology.

ENGEL also promoted fast available stock machines and the new digital assistance systems. These software solutions were also designed as a response to the shortage of skilled labour and provide support in part design, mould testing, production, maintenance and service.

Innovative highlights and exhibits in detail

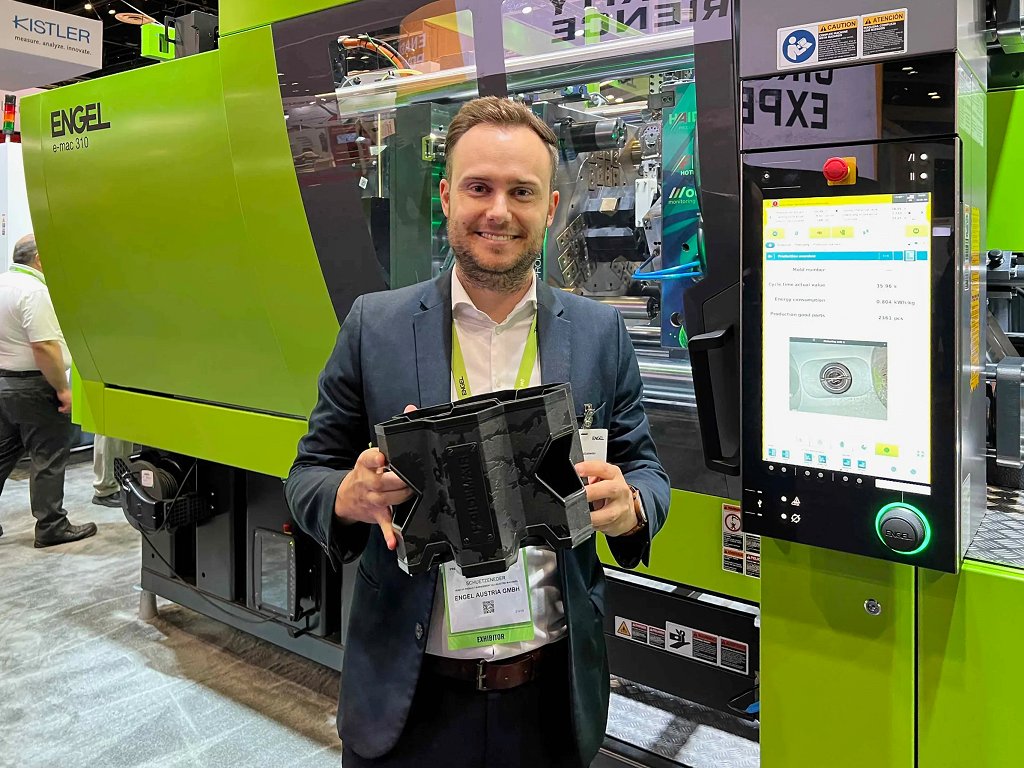

The e-mac slim edition impressed with its compact design. It demonstrated to the participants the advantages of space saving and high efficiency at the same time. Of particular note was ENGEL's recycling package used on the e-mac 1565/310 slim edition, which produced bottle trays from regrind - a first in the industry that closes the loop on plastic materials and minimises CO2 emissions. This machine is proof of ENGEL's ability to combine precision and environmental awareness. This machine demonstrated its strength in producing high-precision technical parts, emphasising the modularity and adaptability of ENGEL's electric machines.

Production of bottle trays from regrind with an ENGEL e-mac 310 slim edition / Exhibit NPE 2024

Production of bottle trays from regrind with an ENGEL e-mac 310 slim edition / Exhibit NPE 2024

With the e-speed 610/90, ENGEL presented an injection moulding machine for packaging that demonstrated its capabilities at high injection rates and pressures. This makes it ideal for high-performance applications. Its hybrid drive concept combines the advantages of electric and hydraulic drives. This enables high productivity and energy efficiency at the same time. Equipped with a 4+4-cavity family stack mould, the e-speed produces tamper-proof food containers and lids with in-mould labelling (IML). Thanks to its unique hybrid drive technology, it is ideally suited for applications that place the highest demands on injection performance.

Production of tamper-proof food containers with an ENGEL e-speed 610 / Exhibit NPE 2024

Production of tamper-proof food containers with an ENGEL e-speed 610 / Exhibit NPE 2024

Another highlight for the visitors was the tie-bar-less victory 330/85 with its quick mould change system. With this system, ENGEL emphasises its commitment to cost efficiency in production. The exhibit also featured an integrated RFID system, which enables automatic recognition and adjustment of machine settings without the need for manual intervention. This drastically reduces changeover times and minimises human error. The tie-bar-less design maximises the space for moulds and facilitates access, which further shortens changeover times and improves operating efficiency. ENGEL is making a clear statement in favour of high user-friendliness.

Quick mould change system with a tie-bar-less ENGEL victory 330/85 / Exhibit NPE 2024

Quick mould change system with a tie-bar-less ENGEL victory 330/85 / Exhibit NPE 2024

Another very remarkable exhibit was the e-motion 440H/160TWP combi M. It attracted attention with its innovative cube mould, which makes it possible to produce highly complex two-component products in the smallest of spaces. This high-performance, all-electric machine with a horizontal rotary table produced diagnostic cartridges under cleanroom conditions. The combi M design, which divides the clamping area of the machine, enables the parallel operation of two mould halves, efficiently doubling the output and illustrating ENGEL's advanced two-component injection moulding technology. It is a prime example of ENGEL's leading role in the development and manufacture of solutions for cleanroom applications, particularly in the medical and diagnostic industries.

Future-orientated technologies and circular economy

In addition to the exhibits, ENGEL also sent out a strong signal in favour of sustainability and solutions for the circular economy. The company presented several initiatives to reduce its ecological footprint through improved recycling technologies and the use of bio-based materials in production. ENGEL is committed to environmentally friendly manufacturing practices and supports customers in achieving their own sustainability goals in order to strengthen their competitiveness. The award of Ecovadis Platinum status underlines ENGEL's leading role in sustainable plastics processing.

Answer to the shortage of skilled labour

The digital assistance systems and advanced automation solutions on show at the NPE focus on increasing efficiency in plastics processing and minimising human error. These technologies make it possible to handle even complex tasks with fewer personnel. They help ENGEL's customers to work more productively and at the same time reduce their dependence on qualified labour.

Local presence and customer proximity

ENGEL's investments in local production and service centres were also highlighted at the trade fair. With assembly plants and service centres in North America, ENGEL is demonstrating its proximity to its customers. These centres play a crucial role in providing fast and efficient responses to customer needs. The location in York, Pennsylvania, serves as a key point for the assembly of customer-specific solutions. The office and technology centre in Corona, California, have been modernised and a new plant is being built in Queretaro, Mexico, whose capacity will benefit not only North American but also South American customers.

ENGEL Exhibition stand with Team / NPE 2024

ENGEL Exhibition stand with Team / NPE 2024

Customer-focused portfolio of fast delivery stock machines

Many of ENGEL's pre-configured machines and robots are immediately available, emphasising ENGEL's commitment to fast and efficient solutions. This comprehensive offer of stock machines covers a wide range of applications and enables ENGEL's customers to respond quickly to their own customers' demands.

ENGEL's commitment to innovation and quality is unrivalled. With a tradition of almost 80 years in the plastics industry and an extensive patent portfolio, ENGEL remains a reliable partner for its global customers. Continuous investment in research and development secures ENGEL's position at the forefront of technology development in the plastics processing industry. The trade fair success at NPE2024 has impressively confirmed this.

Photos: ENGEL