3D Printed Smart Mechatronic Tool for Polymer Materials

06.10.2022

The main objectives of the project “3D Smart IoT TOOL” were to develop and produce a smart mechatronic tool for the production of complex products and to ensure added value for our customers.

An essential element in the production processes of modern factories are the so-called advanced and smart mechatronic tools, which are turning into complex mechatronic systems with the function of monitoring process parameters, controlling the operation and communicating with other machines and external devices. The so-called smart automated factories cannot be efficient enough, for a smart machine without a smart tool is useful only to some extent. By developing this smart mechatronic tool, our company MARSi has reached a new milestone and has come one step closer to becoming a factory of the future.

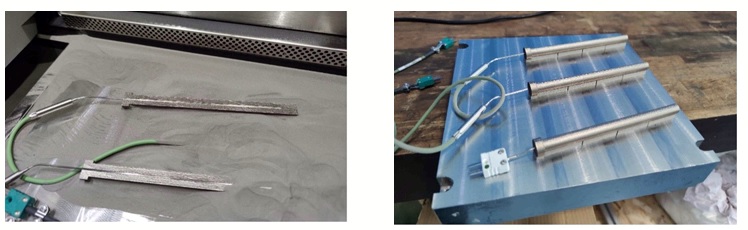

We developed a new tool, whose parts were produced by 3D metal printing, more specifically with the DMLS technology and the EOS M280 EOSINT machine. During the 3D printing process, sensors were directly inserted into the tool parts to measure various parameters, such as air pressure, temperature and vibrations. All sensors have the option of communicating with the IoT module, which shows actual values during the injection molding process.

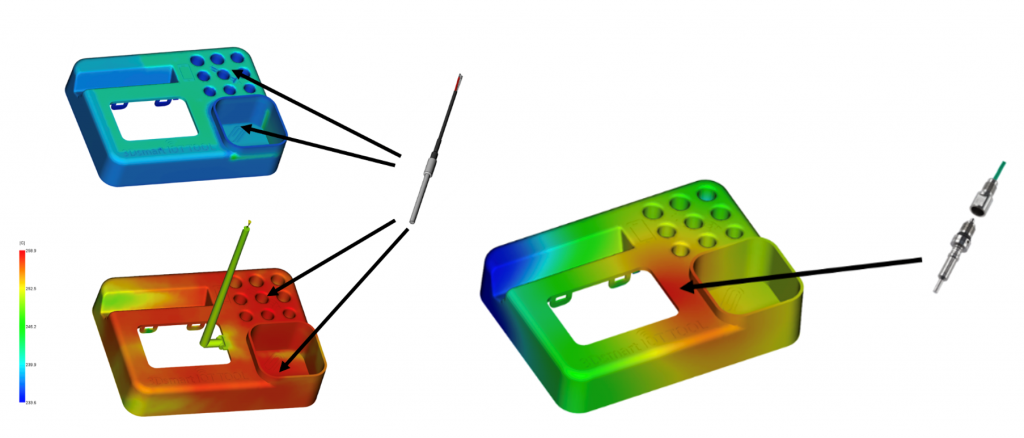

The picture below shows the locations of inserted temperature and air pressure sensors near the mold cavity on the injection side:

Furthermore, we developed an innovative solution to integrate the temperature sensor into the ejector using the 3D-DMLS printing process.

The integration of a sensor into plastic injection molding tool parts during the 3D-DMLS printing process is an innovation in the tool industry both in Europe and worldwide.

The temperature and pressure sensors were directly connected to the IoT communication module on the tool, which sent real-time data to the so-called cloud. At the same time, during the injection molding process, we tested and supervised their performance and monitored closely the process of injection molding.

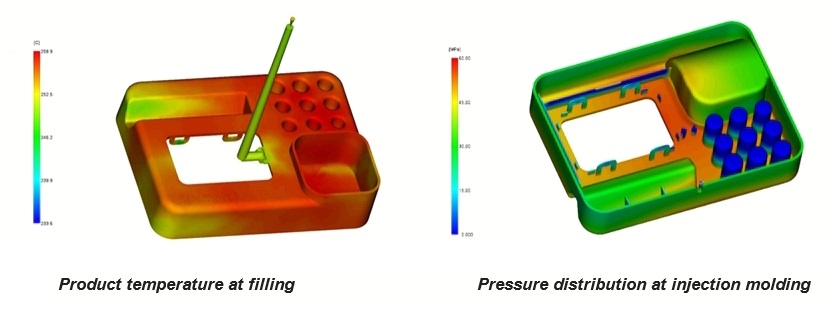

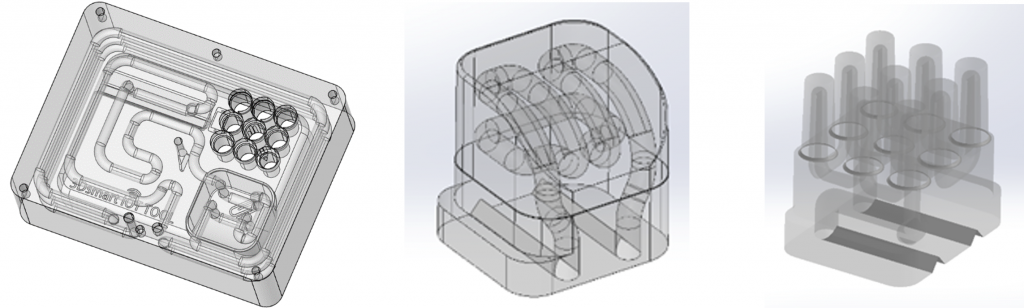

Before making the tool, we defined the injection molding process of the product with the use of simulation tools, determined the optimal cooling channels in the tool (conformal cooling) with additional injection molding simulations, identified the shrinkages, selected the material and, according to the critical locations in the simulation and the 3D printing capability, specified the optimal locations for the installation of sensors. We then used the optimized design to build a smart mechatronic tool with integrated sensors.

A tool, developed in this way, can be produced by 3D-DMLS printing. It can be integrated into state-of-the-art injection molding processes. Optimally designed mold inserts with 3D conformal cooling channels are produced by joining the layers of powder, or more precisely by the revolutionary DMLS technology.

As part of the “3D Printed Smart Mechatronic Tool for Polymer Materials” project, we have completed the development of a high-tech tool and product. The product, developed with the smart tool, is the “Multifunctional Office Desk Organizer”.

It is a product of a team of professionals, hungry for knowledge, success, innovation and progress. The team’s year-round commitment can be seen in all phases of the project as well as in the continuous upgrades of our business.

The operation was selected for EU co-funding under the call for “Incentives for Research and Development Projects 2”

The investment is co-financed by the Republic of Slovenia and the European Union under the European Regional Development Fund (www.eu-skladi.si)

Vir: marsi.at