Arburg at Plastpol: Focus on digitalisation and automation

30.03.2022

• Medical technology: High-speed pipette production on Allrounder 520 H

• Packaging: Small crinkle box on Allrounder 570 A

• Digitalisation: Demo version of arburgXworld customer portal

The exhibits that Arburg has prepared for Plastpol 2022 in Kielce, Hall E, Stand E-30, from 24 to 27 May, cover the entire spectrum of modern injection moulding production. The focus will be on medical technology and packaging with automated sequences and digitalisation via the powerful arburgXworld customer portal.

Commenting on the importance of Plastpol, Konrad Szymczak, Managing Director of Arburg Polska Sp. z o. o. in Warsaw, says: "The Polish market is developing constantly and at the moment we are noticing increased industry interest in energy-efficient solutions, turnkey systems, and sustainable technology. This is reflected in our trade fair exhibits. With the medical technology system based around our hybrid high-speed Allrounder 520 H and the packaging application with a high-precision electric Allrounder 570 A, we are showcasing two automated production examples that ensure high-performance and production-efficient series production of plastic parts in two key sectors of the Polish market."

Konrad Szymczak adds that Plastpol will also feature the trade fair premiere of Arburg's Gestica control system for Poland and its assistant packages to support operators as well as a demonstration of the arburgXworld customer portal and its extensive features. "Digitalisation and automation in injection moulding production – these are the key areas that the Polish injection moulding market is calling for. And the product range that we are showcasing at Plastpol matches this perfectly", he explains.

The hybrid Allrounder 520 H produces 32 pipettes in a cycle time of around six seconds at Plastpol.

The hybrid Allrounder 520 H produces 32 pipettes in a cycle time of around six seconds at Plastpol.

High-speed medical technology application: Pipette tips

As an example from the medical technology sector, Arburg will be exhibiting a hybrid Allrounder 520 H with 1,500 kN clamping force and size 290 injection unit, which produces pipettes in a cycle time of around six seconds using a 32-cavity mould from Zahoransky, a long-standing Arburg customer. This configuration enables a throughput of around 19,200 moulded parts per hour to be achieved. As a complete production cell, the system features, among other things, a clean-air module with ionisation that can be moved above the clamping unit. The hybrid Allrounders combine electrical speed and precision on the clamping side with hydraulic power and dynamics during injection – making them perfectly suited to the needs of medical technology.

Maximum precision in packaging: Small crinkle box

The second exhibit, also automated, is an electric machine from the Alldrive series. The Allrounder 570 A has a clamping force of 2,000 kN and a size 800 injection unit. The system is completed by a Multilift Select robotic system with a load capacity of six kilograms for part removal and set-down. This configuration creates a 'crinkle box': a small container with an outer appearance that looks like a crumpled paper bag. A single mould from Arburg's cooperation partner Haidlmair, Austria, is used to produce this moulded part.

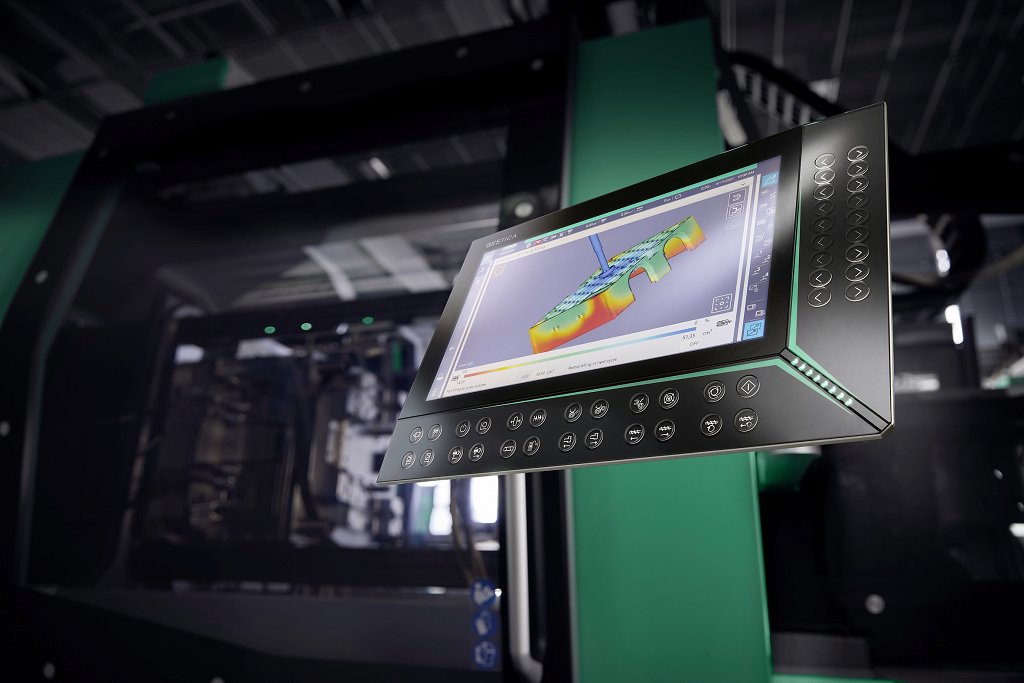

Highlight: Gestica controller

The electric Allrounder is equipped with the Gestica, Arburg’s latest controller generation. aXw Control FillAssist and other assistance systems for the machine operators will also be on show.

The “aXw Control FillAssist” feature on the Gestica saves even experienced set-up technicians valuable time. When the operator imports a part's STL file into the controller, a mould filling study is created and the appropriate injection parameters for the machine and process are determined. This way, all machine users get their first good parts quickly and reliably. During injection, the monitor then displays the filling pattern of the part depending on the screw position.

Control system of the future: The Gestica offers a wide range of assistants, including the "aXw Control FillAssist" that enables filling simulations directly on the screen of the control system.

Control system of the future: The Gestica offers a wide range of assistants, including the "aXw Control FillAssist" that enables filling simulations directly on the screen of the control system.

Digitalisation: Demo version of arburgXworld customer portal

At the Arburg stand, visitors to Plastpol will also find out how digitalisation can be achieved in a practical way in modern injection moulding companies. A demo version of the “arburgXworld” customer portal will be on hand for live testing. Among other things, up-to-date online information on the machine fleet can be accessed from anywhere, whether at the workplace or on the move. Faults can be remedied around the clock using the various apps. And spare parts can also be conveniently ordered directly online 24/7. In addition, calculation tools and knowledge bases are available in various packages for individual compilation. This makes work as easy as possible in many areas of the company.

Arburg: Everything from a single source

Konrad Szymczak believes that Arburg will be very well positioned at Plastpol 2022, commenting: "With our exhibits, we will show every visitor, whether they are owners, managing directors, production managers, machine operators or other specialist personnel from injection moulding companies, the latest possibilities for shortening set-up times, reducing rejects, increasing quality, digitalising their production and so producing even more efficiently."

Konrad Szymczak believes that Arburg will be very well positioned at Plastpol 2022, commenting: "With our exhibits, we will show every visitor, whether they are owners, managing directors, production managers, machine operators or other specialist personnel from injection moulding companies, the latest possibilities for shortening set-up times, reducing rejects, increasing quality, digitalising their production and so producing even more efficiently."

In addition, Arburg offers everything from a single source. Its subsidiary in Poland advises and supports its customers directly with training courses, a well-organised service team, and high spare parts availability. According to Konrad Szymczak, the Polish market offers huge potential: "That's why we want to inspire our customers here with our new products and help them to increase their production efficiency economically, but also sustainably."

Photo: Arburg

Further information about Arburg can be found at www.arburg.com