How Husky Multi-Layer technology helps carbonated soft drink manufacturers drive sustainability

31.08.2021

Many of the world’s largest carbonated soft drink (CSD) manufacturers have set ambitious goals for transitioning to more environmentally sustainable packaging.

As a key packaging supplier for the CSD industry, the drive for greater sustainability has presented Husky with a unique opportunity to take a leadership role in the development of injection molding technology designed to help CSD manufacturers achieve their environmental goals. Husky engineers have embraced this challenge, and have developed Husky’s innovative, industry-leading multi-layer technology.

The shift toward greater sustainability

Many factors are driving the increased use of sustainable packaging for CSDs. Environmental concerns and regulations, consumer demand, and others, are inspiring CSD manufacturers to continuously evolve their go-to-market strategies, and develop extensive plans to make their product packaging more sustainable.

In its 2020 Business and Environmental, Social and Governance Report, Coca-Cola states its goal of reducing its use of virgin PET by a cumulative three million metric tons globally by 2025. In PepsiCo’s 2020 Sustainability Report, the company outlines its plans to achieve net-zero emissions by 2040. And Keurig Dr Pepper’s Sustainability Report details the company’s goals of converting 100% of its packaging to be recyclable or compostable, and to achieve a 20% reduction in its use of virgin plastic across its plastic packaging portfolio by 2025.

The challenge of creating sustainable packaging

Balancing package performance and integrity with sustainability is a major challenge. To achieve balance, a CSD package needs to have a low carbon footprint, must have a strong barrier to ensure product shelf life, and must be recyclable. Glass and aluminum do well at ensuring the shelf life of a product, but have a high manufacturing carbon footprint. Plasma-coated PET bottles usually come with a large capital investment and reduced flexibility. And monolayer PET bottles, though sustainable, don’t adequately protect CSD products.

Husky’s innovative multi-layer solution

Seeing a gap in the market, Husky partnered with Mitsubishi Gas Chemical Company, Inc. (MGC) to develop a multi-layer PET preform designed for small- to mid-sized carbonated beverages.

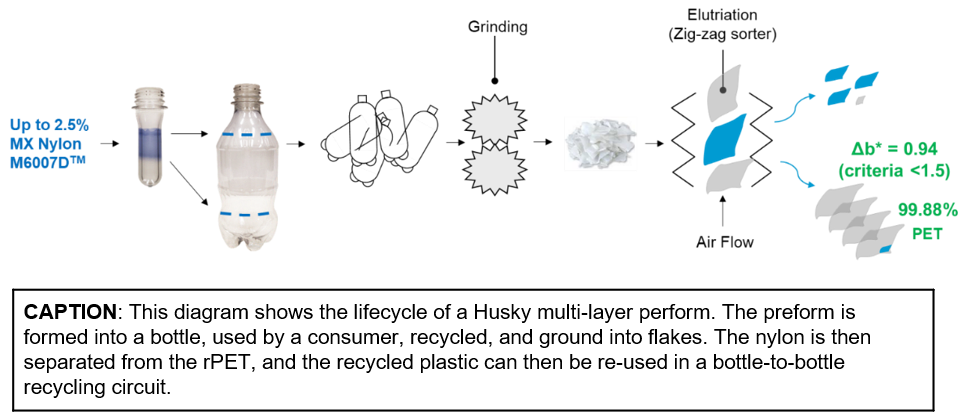

The innovation, which contains two layers of PET surrounding a core of nylon, relies on the advanced melt flow control capability of Husky’s HPP5e multi-layer system and the excellent CO2 barrier properties of MGC’s MX Nylon M6007D. A small amount of nylon, up to 2.5 per cent of the total weight of the package, is molded as the core layer of a PET preform. Precise control of the leading and trailing edges positions the barrier within the thin side walls and keeps the barrier out of the thicker neck finish and the bottle base. The final product contains a barrier that ensures the shelf life of the product and the almost complete separation of PET and nylon during the recycling process.

Results

Testing with 12oz CSD bottles shows Husky’s multi-layer preforms can increase shelf life by up to six weeks, while reducing PET weight by more than 20%, compared to a monolayer package. And the resulting rPET contains only trace amounts of nylon, which is formulated to limit color shift and meet the strict guidelines of the Association of Plastic Recyclers*. Based on these test results, Husky’s multi-layer PET preforms provide a considerably more sustainable alternative to metal cans (the most common form of packaging for sub-355 ml/12 oz beverages).

Husky – your partner in sustainable packaging

Husky is committed to developing packaging solutions that improve recyclability, enable a circular economy, help our customers achieve their sustainability goals, and reduce the use of virgin plastic.

If you’re interested in seeing how Husky’s multi-layer technology can help you achieve greater environmental sustainability and longer product shelf life, get in touch today.

*APR recognition requires both an HPP5e ML system and MX Nylon M6007D, used together. It does not apply for competitor molding systems or different barrier materials.