Cutter Considerations for Hybrid Additive Manufacturing

04.01.2021

Four tips for applying the right cutting tools in hybrid additive manufacturing.

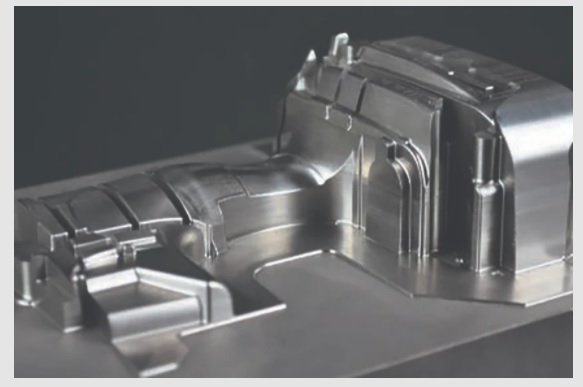

Hybrid additive machining facilitates new design possibilities, such as a one-piece design of a component, complex internal structures or material properties. Image courtesy of Matsuura Machinery USA.

Hybrid additive machining facilitates new design possibilities, such as a one-piece design of a component, complex internal structures or material properties. Image courtesy of Matsuura Machinery USA.

Select end mills that are specially designed with the right geometries, tool material and coatings that are suitable for machining molds and components that have been additively manufactured. Image courtesy of EMUGE Corp.

One of the significant advantages of using hybrid additive manufacturing (AM) is the cost-savings associated with reducing machining waste/scrap. Consider a machinist placing a block of steel weighing 100 pounds into a CNC machine and the finished manufactured part weighing only 25 pounds. That is 75 pounds of scrap being tossed in the chip bed! The cost of material, logistics, time and scrap disposal all add up. For these reasons alone, it may be time for your shop to take a closer look at hybrid additive manufacturing.

One important aspect of any hybrid AM system is the cutting tool technology. Cutting tools have evolved to support the subtractive part of the additive process and offer geometric shapes and coatings relative to the layering process with the abrasive properties and toughness of the sintering procedure.

For optimal results, select end mills specially designed with the right geometries, tool material and coatings that are suitable for machining molds and components that have been additively manufactured.

Applications include a range of materials such as tool, stainless and cobalt chrome steels, nickel-chrome-iron, titanium and aluminum alloys.

Here are four tips for applying the right cutting tools in hybrid additive manufacturing:

1- Ball-nose and radius end mills with a special neck design, cutting edge contour and coating are good choices. A pre-milling end mill with ball-nose geometry targets roughing and pre-finishing operations in order to produce a specific machining allowance on the additively manufactured component. The machining direction here is from top (Z+) to bottom (Z-).

2- A finishing cutter, also with ball-nose geometry, is recommended for finishing operations in construction layers no longer subject to thermal stress. The cutting area of the tool should be designed so that pull machining from bottom (Z-) to top (Z+) is possible in order to finish the material layers that are no longer thermally stressed.

3- A "back taper" radius end mill is suitable for 2D machining of undercuts on the component. Its specifications are aimed at pre-finishing and finishing applications on additively produced components.

4- Some hybrid additive manufacturing applications may require solid carbide micro end mills that are designed to meet the unique and demanding requirements of micro machining applications. In this case, micro end mills with a specific neck geometry enable the optimal application of these tools even in deep contours. A high radial bending strength allow the tools to withstand alternating radial stress on the cutting edge and on the relieved neck during the machining process. A newly developed ALCR coating provided exceptional wear resistance for long tool life.