IRT3000 49/2014

• Revolutionary rotary nozzle with internal action

• From tubes to environmentally and consumer-friendly packaging

• Sun always shines on TV ... and in cities too!

• Light components for accelerated manufacturing

• Carbon fibre products

• Small sensor, great technology

• Diode lasers still a good choice for automotive body-in-white application

• EuroMold 2013 inspires visitors and exhibitors

• Year of mobility and data

• Quality control at automotive supplier GEDIA

• EuroMold 2013 inspires visitors and exhibitors

Content

| 5 | EditorialEditorial |

| 24 | DIR 2014 industrial robotics days |

| 22 | Changing patterns |

Samo Petrič | |

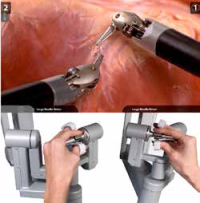

| 20 | Revolutionary rotary nozzle with internal action Instruments for microinvasive surgery are becoming increasingly complex and the reprocessing of such instruments presents quite a challenge. Intuitive surgical leads the way with its DaVinci system.  |

| 16 | Slovenian companies content with Fiat representatives' response

|

| 12 | Project work methods in Slovenian manufacturing companies |

| 11 | Better competitive ability is the only way out of the crisis |

| 10 | Gorenje enters the U.S. market |

| 10 | Free energy? Simple! |

Pulse at Home | |

| 8 | Interview: Gorazd Vrbica, CEO at AlixPartners consulting firm

|

| 31 | About the integration of economy and investments into technological development in Slovenia |

Manufacturing and Logistics

| |

From tubes to environmentally and consumer-friendly packagingLajovic Tuba embalaža, d. o. o. belongs to a group of Slovenian companies with the longest tradition. Milivoj Emil Lajovic, one of Slovenian metalworking and packaging industry pioneers, founded a metal product factory in 1925, which started to manufacture tubes, bakelite seals and raw material for rolled products – ingots and round blanks. Before World War 2, Lajovic's company developed in parallel a packaging program and products for the metalworking industry, a tradition that survived to this very day despite the many technological innovations.  | |

| 34 | Company presentation: Lajovic Tuba embalaža, d. o. o. |

| 32 | Hidria signs a new 21 million contract with VW concern |

| 32 | We are going to be engineers! Inspiring the youth about engineering and innovation |

| 38 | Twin-piston rotary actuator DRRD |

| 40 | Beckhoff EP1816-3008: acceleration measurements made easy |

| 41 | Mid-range IRB 360 FlexPicker™ completes ABB picking robot family now with six variants

|

| 42 | Sun always shines on TV ... and in cities too! A couple of months ago the news were full with stories about a London skyscraper which happens to create local hot spots on nearby objects on a sunny summer day around noon. The hot spots cause overheating of car components, melt bike seats, make tiles fall off building facades and rugs to ignite, while some pranksters even use concentrated solar radiation to fry their eggs.  |

| 45 | XPECTIA FH machine vision system |

| 46 | Efficiency, sustainable development and service robotics at AUTOMATICA 2014 fair |

| 48 | 10. professional convention Handling and assembly automation |

| 61 | NI Compact Vision System |

| 60 | Mean Well MSP-600 series power supplies |

| 57 | 30 years of IGLIDUR® bearings |

| 52 | iQ Mitsubishi platform is the basis for intelligent solutions in the field of robotics |

| 50 | COPA-DATA researches bridging geoinformation and process data |

| 72 | Lightweight and compact drier for small and micro products

|

Non-metals

| |

| 68 | Environmentally-friendly savings in Impol: 250 000 euros/year

|

| 66 | TOX® round joints optimally electrically conductive |

| 64 | Light components for accelerated manufacturing Responding to customer needs for faster and more efficient automated pressroom stamping lines, DE-STA-CO introduces the Accelerate Collection line of lightweight tooling.  |

| 74 | Carbon fibre products The composite industry is rapidly evolving. Only a decade ago, composites were an exotic topic, but today there are many different technologies and materials available, and composite products are finding ways into our everyday life. Their main advantages are low weight and excellent stiffness.  |

| 76 | Molding innovations |

| 77 | Making epilators

|

| 78 | Small sensor, great technology PROMOTECH (Schalchen, Austria) specializes in multi-functional housing components for sensors in automobiles. One example is a combined rain, light and moisture sensor for motor cars.  |

| 80 | SABIC presents new products for the automotive industry |

| 82 | ENGEL Varysoft Day |

| 82 | News from Meusberger |

| 84 | Arburg at Swiss Plastics fair |

| 84 | i-mold at Euromold fair |

| 85 | Kolektor concern sells Kolektor Liv |

| 85 | PIOVAN RYNG – material consumption measurement device |

Welding and cutting

| |

| 86 | Diode lasers still a good choice for automotive body-in-white applications Twelve years ago, a Laserline diode laser was used for the first time in automotive body-in-white (BIW) series production. This initial application was the brazing of the tailgate of the Audi A3.  |

| 88 | An intelligent MIG/MAG welding source generation from Fronius |

| 90 | TIG welding of sheet metal without heat tinting |

| 90 | Varstroj presents Welbee – a new generation of digital welding sources |

| 91 | Innovative welding solution for the nuclear industry |

| 92 | Elektrode Jesenice stick to the realisation of their goals |

| 92 | Herrmann ultrasound unit for robotic welding of thermoplastics |

| 92 | First digital welding dictionary for iOS |

| 92 | Laser welding of transparent polymers |

| 93 | LPKF laser welding moves and expands

|

Metrology & Quality

| |

| 94 | QTree – strong software support for continuous improvements of laboratory |

| 96 | Magnetic rotary encoders contribute to rail track safety program

|

| 100 | Interview: IGOR FIFNJA: |

Nuclear safety at the highest level "We are aware of our responsibility for safe operation of our power plant and follow the principle of social sustainability of our activities." These lines address the visitors of Krško Nuclear Power Plant (NEK) website, informing them about the power plan's two crucial attributes: safety and safety. Safety always comes first and there are a lot of processes related to safety executed daily in the power plant, from observing criteria to rules, laws, procedures ...  | |

| 103 | Non-contact RM22 5 V |

| 104 | The Republic of Slovenia award for business excellence (PRSPO) finalists for 2013 announced

|

Advanced Technologies

| |

| 108 | Year of mobility and data Last year's growth of global IT spending was virtually nil for the first time, while various estimates place it between 3 and 5 percent for 2014. Other indicators predict 2014 will be a year of modest recovery and more temperate technology "evolution". Unofficial estimates of business analysts find the last year's world IT spending stagnating at around 0,4 percent. A business analyst's January report forecasts 3,1-percent growth of IT spending for this year, up to 3,8 trillion dollars. After the last year's decline of 1,2 %, the spending for devices, where Gartner includes desktop and laptop computers, ultrabooks, tablets and mobile phones, will grow by 4,3 % in 2014.  |

| 106 | New SolidWorks Mechanical Conceptual tool |

| 106 | CGS plus and Autodesk partner in the field of mechanical engineering |

| 106 | SAP rushes into the cloud |

| 106 | Autodesk to discontinue software upgrades |

| 107 | IT Awards 2014 |

| 111 | Solid Edge ST6 |

| 114 | New dimensions of consumer electronics |

Pulse Abroad

| |

| 70 | Makino U6: a wire EDM that cuts parts and costs |

| 118 | Vertical challenge

|

| 129 | Quality control at automotive supplier GEDIA Founded in 1910, GEDIA Gebrüder Dingerkus GmbH develops and produces structural parts and assemblies for automotive car body manufacturing. The company is based in Attendorn, Germany, and operates additional production sites in Poland, Spain, China and Mexico. All plants manufacture pressed, stamped and drawn parts for the automotive industry. The company also runs engineering centers in France, the U.S.A. and Sweden. Until today, GEDIA has focused on tactile measurement, using coordinate measuring devices and gauges for quality control of assemblies and in toolmaking. However, this approach to measurement reached its limits as the company grew and expanded its sites. Particularly the inspection of sheet metal parts became time-consuming and labor-intensive, as all parts had to be transported several hundred meters from the press or joining plants to the central measuring room.  |

| 132 | EUROGUSS 2014: More successful than ever |

| 134 | Dimensions of hacking |

| 140 | iMX – exchangeable head end mill |

| 141 | Dormer Shark Line taps

|

| 144 | EuroMold 2013 inspires visitors and exhibitors EuroMold 2013, the World Fair for Moldmaking and Tooling, Design and Application Development, in the year of its 20th anniversary gathered extremely positive responses from trade experts, both visitors and exhibitors.  |

| 145 | Bending and control innovations |

| 146 | AP&T is deepening cooperation with Oerlikon Balzers for the development of different types of coatings |

| 147 | Roughing strategies with optimised tool paths |

| 151 | Tight partnership for a permanent success

|

List of advertisers in 49. number of IRT3000

List of advertisers in 49. number of IRT3000

| 3WAY d.o.o. ABB, d.o.o. ACAM, d.o.o. ANNI d.o.o. ARBURG GmbH AUDAX d.o.o. BASIC d.o.o. Beckhoff Automation GmbH Beogradski Sajam BÖHLER EDELSTAHL GMBH & Co KG PSM d.o.o. BTS Company, d.o.o. Camincam, d.o.o. Celjski sejem d.d. CNC Pro, d.o.o. COPA DATA DATA COM, d.o.o. Elesa+Ganter Austria GmbH FANUC FA Hungary Kft. FESTO d.o.o. FUCHS Maziva LSL d.o.o. HALDER, d.o.o. HELLA Saturnus Slovenija d.o.o. HENNLICH d.o.o. HIDEX, d.o.o. Ib-CADdy, d.o.o. Ib-procadd, d.o.o. Industrijski forum IRT INEA RBT d.o.o. INGVAR d.o.o. ITS, d.o.o. Kern d.o.o. KMS d.o.o. KOLROY Europe | LCR d.o.o. Lakara d.o.o. LESNIK, d.o.o. Letak naklada d.o.o. LOTRIČ, d.o.o. MAKINO Europe GmbH MEM - mechanic & electronic measurement Messe München International Miel, d.o.o. MiniTec, d.o.o. National Instruments PILIH, d.o.o. PS, d.o.o. Logatec Revija EGES Revija Industrija Revija IRT3000 Revija Ventil ROBOS d.o.o. SECO TOOLS Sejem METAV Sejmi Ljubljana - Sejem LOS Siming d.o.o. Solid World d.o.o. TECOS Tehna Plus d.o.o. TEXIMP d.o.o. (HAAS Automation) Tip teh d.o.o. Topomatika d.o.o. VIST d.o.o. WALTER Austria Ges.m.b.H. WEDCO YASKAWA Slovenija d.o.o. Zagrebački velesajam ZIBRT d. o. o. |