| Wearing an IRT3000 T-shirt to the beach

The summer months have passed and we have to adapt to the normal way of work. A surprisingly high quantity of events and other activities in the summer time makes us believe that the companies no longer practice “collective vacations”, business arrangements, various events and presentations namely took place during these hot days as well. During this period, the IRT3000 magazine has visited a number of companies and individuals, who helped with their comments and opinions to make the content of our magazine even better. The importance of contacts between the magazine, its creators and readers has been proved by something I experienced during my vacation at the island of Krk.

You can imagine my surprise when I spotted someone wearing a T-shirt of our magazine in a small village of Porat. We established a contact the next day when I came to the beach wearing an IRT3000 T-shirt, too.

It turned out that Mr. Vinko from Kranj is one of our faithful subscribers, reading the magazine from its very beginning. I also found interesting his incline to order: the company where he works is also subscribed to the magazine, but there are so many readers he had to wait too long to get his turn. Therefore he ordered his own copy so he can dip into it immediately after a new issue is published. Mr. Vinko expressed a lot of praise for the magazine and its content. He also noted that such a magazine was needed long before. He emphasised it is good for the Slovenian area that there is so much information for different fields in a single media, so the reader does not have to order a different magazine for each field. Finally, he wished a lot of success to our magazine, hoping it would keep its present quality.

Such meetings are very important for us who create the magazine, since we can obtain the much needed information about the magazine, about what pleases our readers and about what there is still to improve. At the same time, it is a reward for our work so far and an acknowledgement that we are on the right path. Another proof is the increasing number of magazine and newsletter subscribers. Thank you for all your opinions. We will do our best to keep considering them in the future, too.

Darko Švetak

IRT3000 Editor-In-Chief

From the content:

Interview: Jadran Lenarčič

|

| The influence of process parameters on the properties of products, manufactured using the PIM process Boštjan Berginc, dr. Zlatko Kampuš, dr. Borivoj Šuštaršič

|

| Laser cutting is gaining momentum in the machining of sheet metal

The laser beam is a universal tool for cutting, welding, surface treatment and application of coatings. It operates quietly and does not wear out. Laser cutting produces edges without burr, provides narrow widths of cut and a minimal heat-affected zone. Its advantages also include minimal introduction of heat, low deformations and a high feed rate.

Thematic unit:

|

| Slovenian »in-wheel« engines will power the next generation of electrical and hybrid cars

Elaphe, d. o. o. from Ljubljana has developed a new engine design for direct drive of electrical and hybrid cars based on the ideas of dr. Andrej Detela, bringing many innovative solutions.

|

|

At the end of 2006, the Department of Machining Technology Management at the Faculty of Mechanical Engineering in Ljubljana, lead by prof. dr. Janez Kopač, in cooperation with the Laboratory for Reverse Engineering in making, lead by assoc. prof. dr. Mirko Soković, has acquired a 3D scanner Konica Minolta VI-9i. The scanner enables 3D-digitising in various fields. So far, a couple of thousand scanners from this series have been sold worldwide.

|

| 3D-laser digitising |

|

In the beginning of the nineties, TPV, d. d. has evolved from a manufacturer of special vehicles into one of the leading suppliers of automotive components in Slovenia. Today, the TPV group includes the umbrella company TPV, d. d. and five daughter companies, three of them co-owned by foreign partners. The production is based on manufacturing of automotive seats and their components, as well as metal parts for the automotive industry. This activity represents 80 percent of the

total sales of the group, which amounts to more than 152 million Euros in 2006. The remaining part of the sales is realised through the production of light cargo trailers and through sales and servicing of vehicles. “This year and last year have been a breaking point for the TPV Group in many regards. We have set a new strategy for the period between 2007 and 2011, established the final phase of preparations for the serial production of new twingo and launched the manufacturing in our first company abroad”, explains mag. Marko Gorjup, the member of management board responsible for manufacturing and controlling.

|

| TPV Novo mesto Group, New twingo has brought many changes to the TPV group Sonja Sara Lunder, photo Blaž Košak |

|

Gorenje Toolshop has been manufacturing moulds for forming expanded polystyrene packaging for the last four years, after a new team was formed for the project. Following the initial tests, this project has demanded a lot of ideas and innovation to meet the manufacturing time deadlines and, especially, to achieve minimum material and manufacturing costs.

|

| Optimising the manufacturing of moulds for expanded polystyrene products |

| The state must create a market for innovationSonja Sara Lunder, photo Blaž Košak

The central task of Jožef Stefan Institute (IJS) is intense collaboration in the stimulation of development of technology and economy in Slovenia. Its role is indicated in the training of human resources, as well as in developmental research intended for the users, in scope of which the researchers use their knowledge to help the economy in solving complex problems. The recent past was not too favourable towards the cooperation between the scientific and research circles, but in the last years both sides are discovering the advantages of knowledge, human resource, equipment and organisational exchange, as well as of joint taking part in international projects. The institute stimulates cooperation through various activities.

|

| |

| Injection moulding using a medium (GIT, WIT) Aleš Marinčič, dr. Zlatko Kampuš

|

|

The development of new products with a high value-added must be the goal of every Slovenian company that wants to survive in the global market. One of the possible courses of action is the implementation of new technologies, bringing numerous advantages in comparison with the conventional procedures. One of them is the powder injection moulding process, which combines the forming capabilities of polymer injection moulding process with the mechanical properties of harder metal and non-metal materials.

Advanced technologies:

|

| Powder injection moulding Boštjan Berginc, Dr. Zlatko Kampuš, Matjaž Rot |

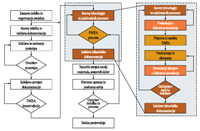

| Quality comes first, what about productivity? Boštjan Demšar, Tomaž Stanonik, Dr. Tomaž Perme

Successful companies striving to achieve competitive advantage in the world market are constantly looking for new ways and solutions to improve the quality of products and increase the productivity and efficiency of manufacturing systems. Without any doubt, automation is the path chosen by the best companies in their branches. Naturally, we can not avoid human presence, just as we can not avoid modern technologies.

Non-metals:

|

| Tempering of moulds with thermo-electrical modules Boštjan Žagar, dr. Gašper Gantar

Avtomatizacija in informatizacija:

|

| 2K injection moulding |

| Welcome to tomorrowness! |

| |