OCS & Mondi: Clever use of defects – integrated quality and production monitoring

19.08.2020

For more than two decades now, the intensive partnership between Mondi and OCS has been cultivated for the benefit of both parties. OCS and the global Mondi Group have concluded a cooperation agreement and work on further developments has been ongoing in a continuous exchange at the management level. Mondi is a leading packaging and paper group and the plant in Gronau specialises in hygiene components, advanced technical films, label films, as well as decorative and flooring films. Mondi Gronau sees itself as a pioneer in the field of integrated process analysis and integration in film extrusion.

INTEGRATED QUALITY AND PRODUCTION MONITORING - TIMELY PREVENTION OF VARIATIONS IN QUALITY.

From the technology for quality and production control to the selfcontrolling machine, Mondi already implements this with the help of OCS components. The basis is provided by the sophisticated inspection technology using the OCS Web Inspection System FSP600, which detects and marks defects and immediately alarms the operator. However, a simple and user-friendly teach-in software is also essential. Defects are detected and classified accordingly.

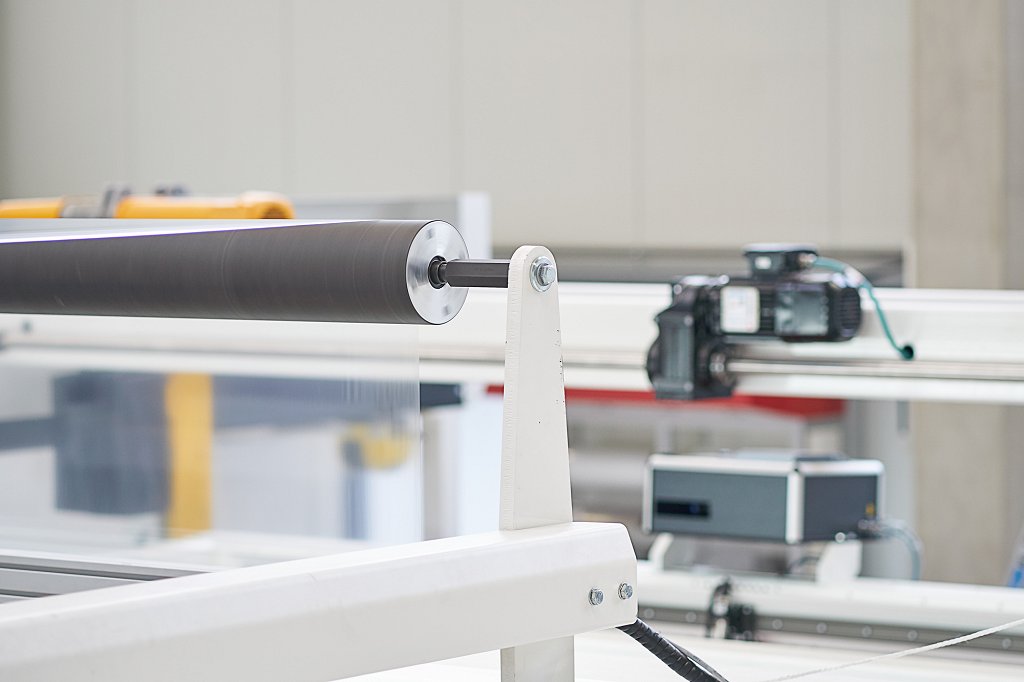

OCS Web Inspection System (FSP600) – Installed OCS camera in film line

Mondi Gronau sees itself as a pioneer in the field of holistic process analysis and integration in film extrusion. "OCS Inspection Systems provide the basis for our process control. By means of the extended networking of complete data stocks from the OCS analysis software and our PDA system, we can react faster to quality variations and assist in the reduction of scrap, rework and machine downtimes, Olaf Brauckmann, Head of Technical Service at Mondi Gronau.” Meanwhile almost all extrusion and converting lines are equipped with OCS inspection systems which support the daily quality assessment. The machine operator is informed about process variations in good time and can counteract quality changes. All inspection systems have an interface to the company's internal production data acquisition system (PDA), so that each reel change is automatically stored with the respective roll number.

OCS Web Inspection System (FSP600) - Process integrated control unit

The complete traceability is given and supports the acquisition of information. Film rolls can be automatically locked by the system without operator intervention. This is made possible by additional analysis software, which relates material, raw material and process parameters from the PDA system to the respective quality/film grade and leads to long-term statistical process control.

FURTHER USE OF OCS SYSTEMS IN THE PRODUCTION PROCESS:

a) Raw materials will be inspected “inline” by an OCS Pellet Scanner (PS800C)

OCS Pellet Scanner (PS800C) - Detects impurities in highly transparent and opaque pellets

b) Compounds will be analysed “offline” by OCS Laboratory Extrusion Lines

OCS Laboratory Extrusion Line – Detects optical errors in extruded films and measures for example haze, gloss, film thickness, etc.

Source: www.ocsgmbh.com